Woodturning - woodworking explained in brief

Woodturning is, in addition to processing forms such as carving, hewing, planing, sawing or milling, a way to produce a round shape from a wooden blank or other suitable workpieces. The material is removed by placing a turning tool on the rotating blank in the woodturning machine or lathe. The finished shape can then be sanded, painted, varnished or decorated with fire painting. Turned workpieces can be bowls and plates, candlesticks and similar home accessories. Chairs and tables also get artistic legs with it, rooms at will elaborate room dividers. Children are especially familiar with small disc animals, which are pre-turned by turning on a large wooden wheel, then cut off, finish sanded and painted.

Woodturning lathe for clamping and turning the workpiece

For turning, the workpiece is clamped in a lathe and turned. In our range we offer small table lathes, for example for school workshops or hobby workshops, and large hand lathes, which are also used by craftsmen with high performance requirements. Based entirely on individual requirements for heaviness, size and frequency of use, Steinert lathes are currently offered in piccolo, gamma & VGM, hapfo, VB36, maximo and Killinger models. The Steinert foot lathe is a historical replica of what were once typical art workshops in the Erzgebirge region. Hobby artists and craftsmen can also assemble their own foot lathe with kits.

Woodturning machines - all-rounders among the automatic lathes

Despite ever new, artificial materials, wood remains an integral part of daily life and the fashion industry. Steinert lathes are suitable for small turning jobs, for example for the handles of kitchen utensils or shaving accessories. Via individual adjustment, they can likewise be used for large wooden products such as table and chair legs, ornate door jambs, and similar woodturning projects. The quality of Steinert's woodturning machines is guaranteed because they are manufactured in the company's own Olbernhau machine store, where they are thoroughly put through their paces. Which machine is best suited for turning is best determined in a detailed consultation. For special needs, individual productions especially for a manufactory or a mass producer in the wood craft are also possible.

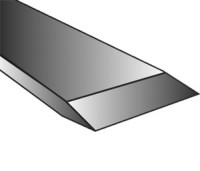

Woodturning tools - the counterpart to the woodturning lathe

Woodturning lathes and woodturning machines turn the workpiece. It is worked with turning tools, for example roughing tubes, chisels, gouges and other tools that are also used for hand carving. However, unlike these hand tools, they are more robust with equally strong steel quality of the tool blades. Woodturning tools are available in the range for rough woodturning or for delicate fine work. What is practical about the size and shape of woodturning tools is that they also provide valuable and precise services for hand carving - for example, for notch carving or sculpting work. What is practical about woodturning tools is the ergonomic shape of the wooden handles. These fit in the hand in such a way as to reduce fatigue even over long periods of machining.

Chuck for fixing different workpieces

In order to be able to process a wooden surface by woodturning, it must rotate, but must not slip out of position. This is prevented by a suitable chuck. This is where the workpiece is clamped. Depending on the weight of the workpiece, its outer thickness, length and other components, craftsmen and do-it-yourselfers will find chucks to fit all Steinert lathes and lathes. We recommend a set of different designs to be able to switch between different workpieces as required when turning. Assortment examples of this category are two-jaw chucks, threaded inserts for Patriot chucks, basic chucks without collets or mandrels for clamping nuts for jewelry making. Also available here are clamping nuts of various diameters to match the Steinert finger ring kits.

Jigs for lathes, woodturning machines and other Steinert machines

The range of jigs includes, for example, jigs for turning tubes, centering jigs for knives or jigs for straight cutting edges. Also indispensable for the craftsman, carpenter or do-it-yourselfer are jigs for bench mounting, for short or long tools, axes or machine planing knives. In machine turning, they all improve the possible precision in the processing of wood blanks and other materials of similar processing quality. The materials and steel qualities used comply with industrial standards. This makes them suitable for heavy, daily use in continuous professional operation. Each model of the fixtures fits exactly to the tool holder. This makes quick changes effortless, even for less experienced woodturning beginners.

Advantages of machines, tools and accessories for woodturning

These advantages characterize the self-made woodturning lathes and woodturning machines in the Steinert Drechselzentrum Erzgebirge as well as tools and accessories:

- Woodturning lathe also ideal for small set-up areas and beginner projects, for example, for creative and handicraft lessons in schools or wood craft lessons in the club

- Woodturning machines in processing and equipment also suitable for craftsmen and industrial mass production

- Turning tools extensively in the assortment for the rough and fine processing by turning at wood workpieces of all diameters as well as for complicated special forms

- Chuck suitable for all Steinert woodturning machines and lathes, robust, in different diameters and easy to change

- Jigs and fixtures for woodturning needs in the range for hobby woodturners and professional workshops, manufactories or joineries and carpentries

- In-house production of Steinert lathes and lathes in our own engineering company, thus continuously high quality guaranteed by in-house control

back to top...