Cookie preferences

This website uses cookies, which are necessary for the technical operation of the website and are always set. Other cookies, which increase the comfort when using this website, are used for direct advertising or to facilitate interaction with other websites and social networks, are only set with your consent.

Configuration

Technically required

These cookies are necessary for the basic functions of the shop.

"Allow all cookies" cookie

"Decline all cookies" cookie

CSRF token

Cookie preferences

Currency change

Customer recognition

Customer-specific caching

Individual prices

PayPal payments

Selected shop

Session

Comfort functions

These cookies are used to make the shopping experience even more appealing, for example for the recognition of the visitor.

Note

Permanent cart

Statistics & Tracking

Affiliate program

Conversion and usertracking via Google Tag Manager

Facebook Pixel

Track device being used

etracker Analytics

€284.50 *

Prices incl. VAT plus shipping costs

only 1 in stock available immediately

Estimated shipping tomorrow, 09.10.2025

Order within8 hours and 42 minutes this and other products.

Order within8 hours and 42 minutes this and other products.

Total: *

- Order number: DBS-22

With Tormek's patented drill sharpening device, the DBS-22, you can now sharpen your drills with... more

Product information "TORMEK Device for Grinding Drills"

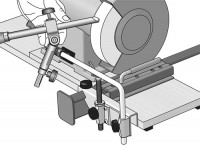

With Tormek's patented drill sharpening device, the DBS-22, you can now sharpen your drills with maximum precision. The optimal point and clearance angles can be set for each drilling process in terms of drill size and material. Even broken bits can be ground into a perfect shape.

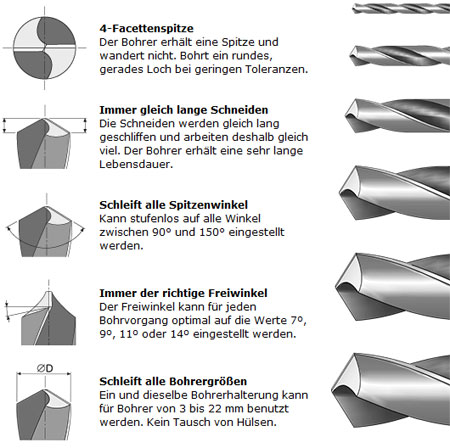

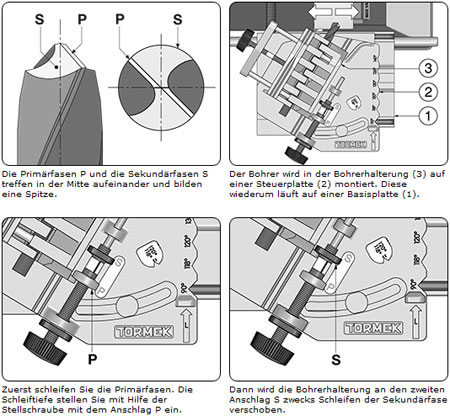

You get a 4-facet tip that has very good cutting properties. The cross-cutting edge of the drill is given a point instead of being basically flat as with conventional drills. The 4-facet tip does not move and requires significantly less drilling pressure when drilling compared to the usual conical tip.

The precision-ground 4-facet tip significantly reduces the generation of heat and therefore the drill lasts much longer. Independent tests show that you can drill up to four times longer with a Tormek-sharpened drill than with a conventional drill¹.

Since you work according to the laws of nature and continuously cool the cutting edge, there is no risk of the steel overheating and losing its hardness or developing microcracks. You always have full control and can see how the grinding process is progressing.

Flexibility and precision

Parts included

Questions and Answers

Why is the 4-facet geometry so advantageous?

It reduces the pressure on the core of the drill, the so-called cross cutting edge, which reduces heat generation and means that more energy acts on the active cutting edges. This dramatically increases the cutting ability of the drill. The better cutting ability is of particular advantage if you work with a hand drill, where you cannot exert as hard pressure as with a column drill.

It reduces the pressure on the core of the drill, the so-called cross cutting edge, which reduces heat generation and means that more energy acts on the active cutting edges. This dramatically increases the cutting ability of the drill. The better cutting ability is of particular advantage if you work with a hand drill, where you cannot exert as hard pressure as with a column drill.

Why does a Tormek-ground drill have a longer service life?

The superior 4-facet point and the high precision when grinding - both cutting edges are ground exactly the same length and symmetrically - mean that the drill and its own work efficiently Service life is extended significantly.

The superior 4-facet point and the high precision when grinding - both cutting edges are ground exactly the same length and symmetrically - mean that the drill and its own work efficiently Service life is extended significantly.

What causes a hole to be drilled exactly and straight?

The 4-facet tip drills a straight and round hole with very low tolerances. It is crucial that the two cutting edges have been ground to the same length and at the same angle. This is a prerequisite for both cutting edges to work equally hard and for the drill to drill a round, straight hole that is no larger than the diameter of the drill. If this is not the case, the longer cutting edge has to exert the greatest cutting force and will overheat and wear out quickly. As a result, the drill quickly becomes blunt and no longer works.

The 4-facet tip drills a straight and round hole with very low tolerances. It is crucial that the two cutting edges have been ground to the same length and at the same angle. This is a prerequisite for both cutting edges to work equally hard and for the drill to drill a round, straight hole that is no larger than the diameter of the drill. If this is not the case, the longer cutting edge has to exert the greatest cutting force and will overheat and wear out quickly. As a result, the drill quickly becomes blunt and no longer works.

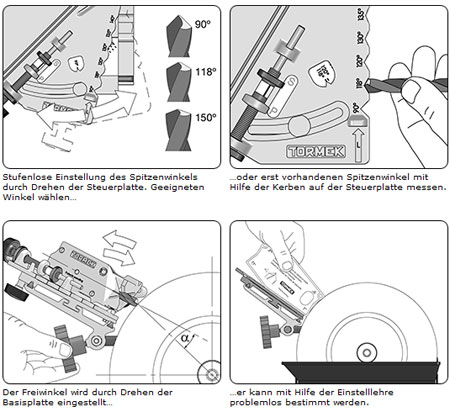

Which point angle should I choose?

Drills usually have a point angle of 118° or 130°. With harder steel and stainless steel you need larger point angles. Aluminum is also best drilled with a larger point angle. If the drill penetrates the material with Plexiglas, the risk of cracks is lower, if the point angle is larger, 140° –150°. Centre drills usually have a point angle of 90°.

Drills usually have a point angle of 118° or 130°. With harder steel and stainless steel you need larger point angles. Aluminum is also best drilled with a larger point angle. If the drill penetrates the material with Plexiglas, the risk of cracks is lower, if the point angle is larger, 140° –150°. Centre drills usually have a point angle of 90°.

Is the clearance angle important?

The choice of clearance angle is decisive for the cutting properties of the drill and its service life. The optimum clearance angle in each case depends on the drill diameter and the material to be drilled. A harder material requires a drill with a smaller clearance angle, while a softer material can have a larger angle. Most drills have a clearance angle of 11° and a point angle of 118°. These work well for most drilling jobs.

The choice of clearance angle is decisive for the cutting properties of the drill and its service life. The optimum clearance angle in each case depends on the drill diameter and the material to be drilled. A harder material requires a drill with a smaller clearance angle, while a softer material can have a larger angle. Most drills have a clearance angle of 11° and a point angle of 118°. These work well for most drilling jobs.

How do you know that the steel has been overheated during dry grinding?

You often do not notice overheating of the steel, but the consequences are the drill quickly becoming blunt or breaking. In contrast to conventional drill grinding machines, Tormek grinds with water cooling, which protects the steel.

You often do not notice overheating of the steel, but the consequences are the drill quickly becoming blunt or breaking. In contrast to conventional drill grinding machines, Tormek grinds with water cooling, which protects the steel.

This is how the device works

You can find many interesting details and recommendations for use on the Tormek website (German).

Product overview TORMEK machines and accessories for Download as PDF file (2.5 MB) ...

Related links to "TORMEK Device for Grinding Drills"

Available downloads:

Read, write and discuss reviews... more

Customer evaluation for "TORMEK Device for Grinding Drills"

Write an evaluation

Um eine Bewertung abgeben zu können, müssen Sie sich zunächst anmelden.

You have last looked at the following articles: