Prices incl. VAT plus shipping costs

only 2 in stock available immediately

- Order number: T-4

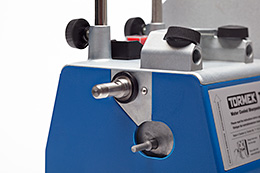

THE TORMEK T-4 is a further development of the T-3 model which brings precision and stability to a completely new level. Important functions, such as the motor and main shaft, are mounted in the cast upper part, and the sockets for the universal support are also integrated. This results in unbeatable precision for the universal support, which serves as the basis of all Tormek devices.

You get a high-quality machine, ideal for home and hobby, which can grind all common cutting tools. The scope of delivery includes the stone grader SP-650, protractor WM-200, peeling paste PA-70, DVD and manual for Tormek wet grinding. Complete the T-4 with your choice of fixtures based on the tools you want to sharpen (sold separately).

Please Note! The technical specifications apply to German-speaking countries and the entire documentation for the machine is in German.

Product overview TORMEK machines and accessories for the Download as PDF file (2.5 MB) ...

Dimension : Width 230mm , Depth 200mm, Height 260mm

Weight : incl. Packaging 9.8kg, machine individually 8.0kg

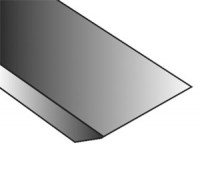

Whetstone : Tormek original whetstone, aluminum oxide, 200 × 40mm, 120rpm, torque 8.4Nm

< strong> Leather honing disc : 145 × 26mm

Main shaft : Main shaft made of stainless steel, EzyLock in composite.

Housing : Solid zinc upper part , Impact-resistant ABS plastic

Motor : Single-phase industrial motor, 120W (consumption) 230v, 50Hz. Operation 30min / h, maintenance-free. Quiet operation , 52 dB. 10,000 hours lifespan

The sleeves for the universal support are now integrated in the cast zinc upper part. Together with the new Tormek construction of the holes (patent pending) the precision has been improved by over 300%.

The handle makes it easy to place or turn the machine if necessary.

The cast zinc top is in the construction integrated.

The machine plate is now off Metal, the place to attach the Tormek angle gauge with its magnetic feet.

How does the T-4 differ from the T-3?

Precision has been improved over 300%

This will improve your control over sharpening - and you will get a better result.

Handle for easy handling

Makes the machine easy to place and handle.

Machine plate in metal

The place to attach the Tormek angle gauge with its magnetic feet.

Device for straight cutting is no longer included in the scope of delivery

Adjust your grinding system right from the start and complete it with the devices you need according to your needs. (For example, if you only sharpen knives, you don't want to pay for a device you don't need)

Stone Graders included (because you need them)

Independent of what you are grinding, you will have to activate the stone if necessary, so we include it from the start. That means, with the stone grader you can achieve two different properties of the whetstone, fast and fine!

How is the accuracy compared to the T-7?

Thanks to the patented With the cast zinc upper part, we have achieved the same accuracy with the T-4 as with the T-7, which is made of 3mm steel and precision-assembled bushings for the universal support.

The T-4 Model comes with the following accessories

Stone graders

Stone graders

WM-200, angle gauge

WM-200, angle gauge

PA-70, peel paste

PA-70, peel paste

manual

manual

Tormek DVD

Tormek DVD

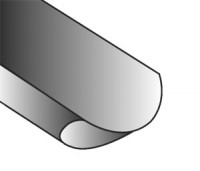

The grindstone:

The grindstone from TORMEK rotates at a slow speed in the water bath. It is ceramically bonded (sintered at high temperature). The abrasive grains are made of aluminum oxide. Grain size 0.06mm. Grit 220. The grindstone grinds extremely effectively and ensures a fine grinding surface for the tool. With this stone you can grind larger tools in a few seconds, e.g. planer knives, axes and scythes, but also tools made of hardened steel and HSS, but not carbide steel. The surface of the grindstone can be refined with the stone grader SP-650 to a grain size of 1000 for fine grinding. The outside of the grindstone is machined and recessed in the middle so that the grinding surface does not collide with the washer and the nut in the center. This completely flat surface is suitable for smoothing the back of plane irons, chisels and similar tools. Due to the diameter of 200mm, the bevel is less concave than with a smaller whetstone. The width, 40mm, gives you a generous work surface for working with your tools.

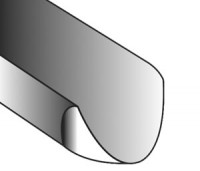

The leather honing disc:

You remove the burr on the TORMEK leather honing discs, on the You apply the TORMEK release paste. The leather gently removes the burr and you get the same perfect sharpness as with the venerable peeler leather and the bevel becomes mirror-like.

You can either sharpen it freehand or leave the tool in the sanding device after sanding. Adjust the grinding device so that the honing can take place at the same angle as the previous grinding.

A tool that has the correct shape and the correct cutting edge angle, but has become a little blunt, can be used directly on the honing wheel without to grind it beforehand. Since you use the device to guide the tool to the honing wheel with great precision, you can press it down firmly without the cutting edge being rounded.

The universal support:

The versatile universal support is the basis of the TORMEK system. It consists of 12mm round steel and is mounted in double guide bushes for maximum stability. The universal support is equipped with a fine adjustment for quick and precise adjustment.

The angle gauge:

This patented angle gauge has two functions. It can be used to adjust the device to the grindstone to grind tools with an optional cutting edge angle from 15° to 75°. It can also be used to measure an existing cutting edge angle on a tool.

It was designed to fit all grinding stone diameters from 255mm to 150mm. You get an exact setting regardless of how worn the stone is.

The angle gauge has two magnets for easy attachment to the machine.

The optional grinding devices:

SVH -320

Device for machine planing knivesFor HSS knives, unlimited length. Minimum width 13mm. Also for miter punching machine knives.

SVP-80

Device for profile knives For surface grinding of all types of profile knives with a center distance of 24, 30 and 38mm between the feed holes. Max. Width 100mm. Also for profiled paint spreader knives.

SVD-185

Device for tubes and exchangeable bladesFor finger-shaped rotating tubes, carving gouges and goat feet. Max. Tool width 25mm. Also for exchangeable blades.

SVS-50

Multi-device for turning chisels, parting tools and roughing gouges. Carving gouges and chisels, 25 - 50mm.

SVS-32

Device for short tools. For straight carving gouges and goat feet up to at least 45mm in length. Also for short chisels and carving tools for electric carvers. Max. Tool width 32mm.

SVD-110

Grinding support with TORLOCK for scrapers. Also for large, special carving tools such as barrel scrapers and curved draw knives. Scrapers. Hollow turning tools.

SVA-170

Device for axes and hatchets. Maximum ax height 170mm.

SVM-45

Device for most knives. Blade length at least 60mm. Also for straight draw knives. Scraper blades, short or with convex cutting edge.

SVM-100

Device for long, thin knives. Stably supports a thin blade. Blade length at least 120mm.

SVX-150

Device for scissors and hedge trimmers. Also for hand planing machine knives.

You will find many interesting details and application recommendations on the Tormek website < / a> (German)