Prices incl. VAT plus shipping costs

only 6 in stock available immediately

Prices incl. VAT plus shipping costs

only 6 in stock available immediately

- Order number: 00322100

| Order number | Preview | size | Price Price | Delivery time | Order quantity |

|---|---|---|---|---|---|

| 00302300 | cutting edge width 8-12 mm, 320 mm long | From 1 €121.50 | currently not in stock Delivery time 30 Workdays | | |

| 00322100 | cutting edge width 14-16 mm, 350 mm long | From 1 €171.50 | only 6 in stock available immediately | | |

| 00321100 | cutting edge width 18-22 mm, 350 mm long | From 1 €142.80 €178.50 | only 7 in stock available immediately | | |

| 00302100 | cutting edge width 18-22 mm, 450 mm long | From 1 €186.50 | more than 10 in stock available immediately | |

Please select the desired tool length (steel length) and cutting edge width!

Please note that the hand-forged tools of the brand "Neuhammer" are delivered without hilt.

Compared to industrially manufactured mass products, please note that dimensions and shape show slight variations due to the manufacturing technology of hand-forging. In addition, cutting edge shape and sharpness of new tools are not yet ready for use. All tools must first be sharpened. This makes it possible to correct the cutting edge shape according to individual requirements (influencing factors such as wood type, workpiece shape and the like).

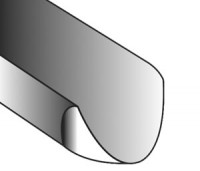

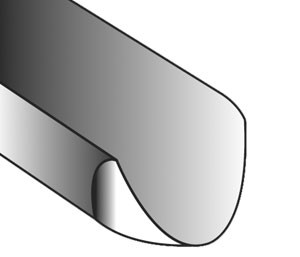

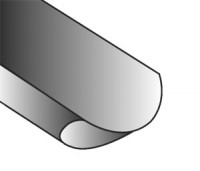

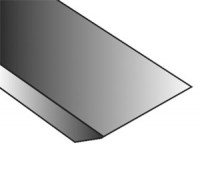

Application: The U-turning gouge, also called shell gouge or crosscut gouge is normally used for processing crosscut wood. In the case of cross-grain wood (as opposed to long grain wood), the grain of the wood lies across the axis of rotation. Thus, different cutting edge shapes are usually required. Crosscutting gouges are more deeply worked than longwood (spindle) gouges. The cross-section is U-shaped. Up to certain limits, crosswood gouges can also be used for hollowing out vase-shaped workpieces.

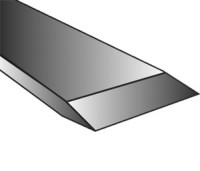

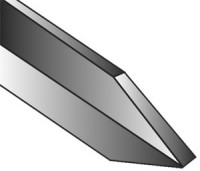

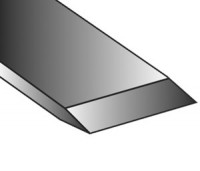

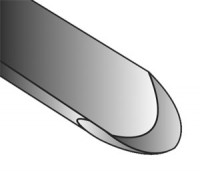

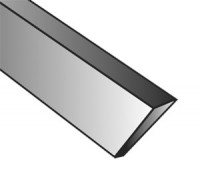

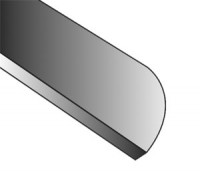

Grinding: The cutting edge shape depends primarily on the shape of the workpiece to be machined. As a rule, the shell gouge is provided with a relatively blunt (large) (45 - 60º?) wedge angle. For elongated shapes a small wedge angle (long guide chamfer) is useful, for narrow cavities a large wedge angle (short guide chamfer). A short chamfer is often used for internal recesses (bowls), which is also broken again at the end or ground in an overall convex shape. A fingernail bevel, i.e. side edges ground back, proves to be expedient for many applications. Especially the application of the tool at the edge of the bowl is often possible more safely and cleanly with a fingernail grind.

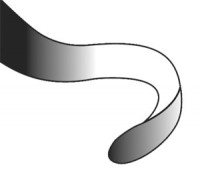

Working method: To make a shell, the wood blank is attached to a screw chuck or faceplate and first turned on the underside. The shell gouge is inclined in the feed direction. The feed direction should be from the center outward on the underside of the bowl; on the face side at the base of the bowl, the feed can also be from the outside inward. It is important for all work with a gouge that the cutting edge bevel is in contact with the workpiece, thus guiding the tool. Once the underside of the bowl has been turned, it is turned over, clamped at the foot and the inside turned out. Here, the feed is normally from the edge of the bowl towards the center. Again, the gouge is tilted in the feed direction and turned into the profile. The cutting edge bevel must be in contact with the workpiece.

For a basic set-up, a width of 14-16mm is recommended.

Examples of use: Bowls, dishes, plates, shooter discs or other disc-shaped objects.

PERFECT!!!!

I am very satisfied!!! I made the handle 450 mm long, great chisel!!!!

Thank you very much for this excellent feedback!

Benutze schon seit langem Neuhammer (vorher Gläser) Röhren und bin mit Ihnen sehr zurfrieden, Qualität und Standzeiten der Schneiden sind sehr gut!

Super

Ein sehr massives Eisen. Mit sehr guter Standzeit, liegt gut in der Hand und macht Spaß!

Danke für ihre Bewertung und noch lange Zeit Freude mit den Neuhammer Schmiede-Eisen.