Prices incl. VAT plus shipping costs

currently not in stock

Delivery time 30 Workdays

Prices incl. VAT plus shipping costs

currently not in stock

Delivery time 30 Workdays

- Order number: 00309200

| Order number | Preview | size | Price Price | Delivery time | Order quantity |

|---|---|---|---|---|---|

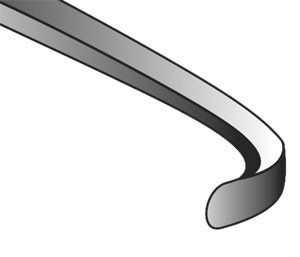

| 00309200 | hook Ø 10 mm, 350 mm long | From 1 €70.00 €87.50 | currently not in stock Delivery time 30 Workdays | | |

| 00309100 | hook Ø 12 mm, 350 mm long | From 1 €92.50 | only 10 in stock available immediately | |

Please select the desired size!

Please note that the hand-forged tools of the brand "Neuhammer" are delivered without hilt.

Compared to industrially manufactured mass products, please note that dimensions and shape show slight variations due to the manufacturing technology of hand-forging. In addition, cutting edge shape and sharpness of new tools are not yet ready for use. All tools must first be sharpened. This makes it possible to correct the cutting edge shape according to individual requirements (influencing factors such as wood type, workpiece shape and the like).

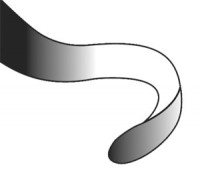

Application: Turning hooks are used for turning out hollow forms in long wood work (end grain). They are used for both roughing and finishing, but require some practice.

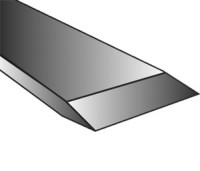

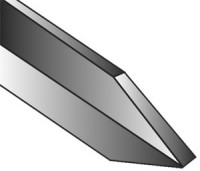

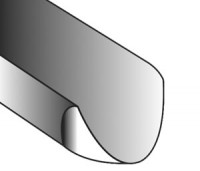

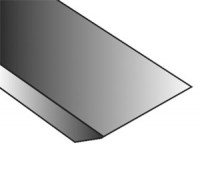

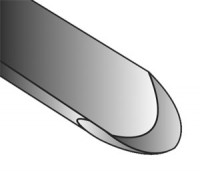

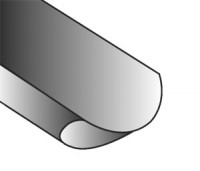

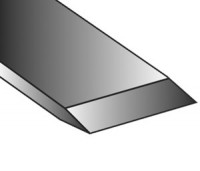

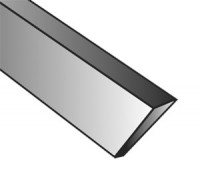

Bevel: These tools have a straight cutting edge that ends in a small hook at the front. The bevel is on the inside. The outer surface is used to guide (contact) the inner workpiece. During sharpening, a grinding wheel rounded on one side is used to grind the inner bevel. Since it is mainly the front hook shape that has to be reground, a grinding cone can also be used there. The outer shape must not be ground hollow but rather round (crowned) so that it can contact the wall of the workpiece as a guide surface.

Method of operation: After turning the workpiece round, the face is cleanly cut off (with the chisel). Then the center is punched and a hole is drilled (diameter larger than the hook size and advantageously almost to the final depth).

With the small rounding of the hook, the hole is approached and machined from the inside to the outside, chip by chip. The cutting edge is upwards and slightly inclined to the center. The back of the hook forms the guide in the workpiece.