Prices incl. VAT plus shipping costs

currently not in stock

Delivery time 30 Workdays

Prices incl. VAT plus shipping costs

currently not in stock

Delivery time 30 Workdays

- Order number: 00307200

| Order number | Preview | size | Price Price | Delivery time | Order quantity |

|---|---|---|---|---|---|

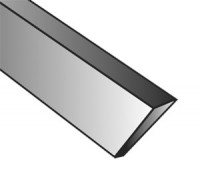

| 00307200 | cutting width 2-3 mm, 250 mm long | From 1 €87.50 | currently not in stock Delivery time 30 Workdays | | |

| 00307100 | cutting width 2-3 mm, 320 mm long | From 1 €74.80 €93.50 | only 4 in stock available immediately | |

Please select the desired tool length (steel length).

Please note that the hand-forged tools of the brand "Neuhammer" are delivered without a handle.

Compared to industrially manufactured mass products, it should be noted that dimensions and shape show slight fluctuations, which are due to the manufacturing technology of the artisanal forging. In addition, the shape and sharpness of the cutting edge are not yet ready for use with new tools. All tools must first be sharpened, this enables the shape of the cutting edge to be corrected according to individual requirements (influencing factors such as type of wood, workpiece shape and the like).

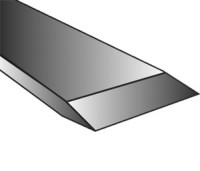

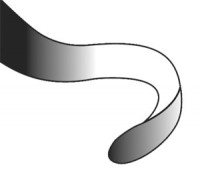

Application: Parting tools are used for parting (separating) the finished workpiece from the remaining piece held on one side in the chuck. This detour with groove achieves a particularly clean cut surface thanks to its cutting effect. It is only suitable for long wood turning.

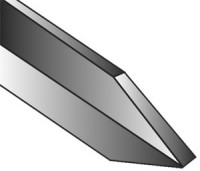

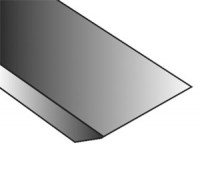

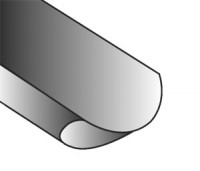

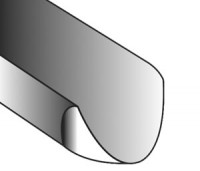

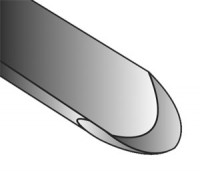

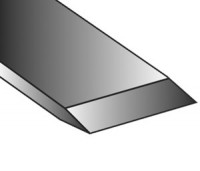

Bevel: The lower side of the wedge-shaped cutting edge is slightly beveled. This ensures that the right side of the cutting edge is slightly in front which is the only way to ensure that the finished turned part is cut cleanly to the axis of rotation. A notch of approx. 45 degrees is ground in the upper side. With the basic grind, the centre of the tip will be in the centre line of the tool. When resharpening, only the lower side of the wedge-shaped cutting edge is ground. Only when the upper notch is too short does it have to be reground. This is done with a narrow (approx. 4mm) grinding wheel that has been trimmed to a point. However, since the parting steel is ground approx. 2 to 3mm thinner from the point to the tang in order to avoid jamming, the notch can only be re-ground up to a certain limit.

Method of operation: The groove is held up and the tip of the tool is pressed in from the periphery to the centre of the workpiece. This creates a cut, similar to a chisel. With larger diameters, some space must be created to the left of the cutting line with the cutting tool to avoid the tool jamming in the groove.