Prices incl. VAT plus shipping costs

only 5 in stock available immediately

Prices incl. VAT plus shipping costs

only 5 in stock available immediately

- Order number: 00308200

| Order number | Preview | size | Price Price | Delivery time | Order quantity |

|---|---|---|---|---|---|

| 00308200 | cutting edge width 3-4 mm, 250 mm long | From 1 €87.50 | only 5 in stock available immediately | | |

| 00308100 | cutting edge width 3-4 mm, 320 mm long | From 1 €74.00 €92.50 | only 7 in stock available immediately | |

Please select the desired tool length (steel length).

Please note that the hand-forged tools of the brand "Neuhammer" are delivered without a handle.

Compared to industrially manufactured mass products, it should be noted that dimensions and shape show slight fluctuations, which are due to the manufacturing technology of the artisanal forging. In addition, the shape and sharpness of the cutting edge are not yet ready for use with new tools. All tools must first be sharpened, this enables the shape of the cutting edge to be corrected according to individual requirements (influencing factors such as type of wood, workpiece shape and the like).

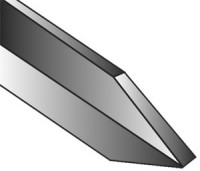

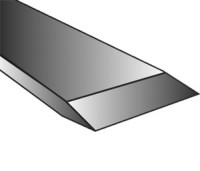

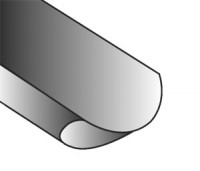

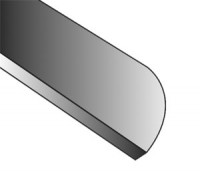

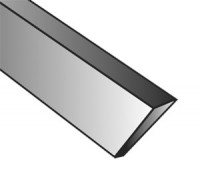

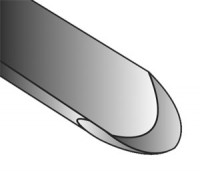

Application: Parting tools are used for parting (separating) the finished workpiece from the remaining piece held on one side in the chuck. This diamond-shaped parting cutter is very stable and easier to regrind than the parting tool with a groove.

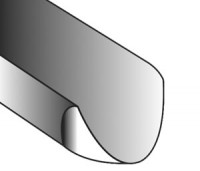

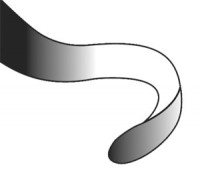

Sharpening: The lower cutting surface must be sharpened at a slight angle so that one side of the cutting edge becomes a little longer. This slightly longer side should face the workpiece side (usually on the right) during the parting process. This is the only way to ensure that the workpiece is cut cleanly up to the axis of rotation.

How it works: The digger is placed high on the periphery of the workpiece and pressed into the wood in an arc to the centre of the axis of rotation. For larger diameters, some space must be created to the left of the parting edge with the parting tool in order to avoid the tool jamming in the resulting groove.