Prices incl. VAT plus shipping costs

currently not in stock

Delivery time 30 Workdays

Prices incl. VAT plus shipping costs

currently not in stock

Delivery time 30 Workdays

- Order number: 00301800

| Order number | Preview | size | Price Price | Delivery time | Order quantity |

|---|---|---|---|---|---|

| 00301800 | cutting edge width 6-8 mm, 250 mm long | From 1 €88.50 | currently not in stock Delivery time 30 Workdays | | |

| 00301700 | cutting edge width 10-12 mm, 320 mm long | From 1 €98.50 | currently not in stock Delivery time 30 Workdays | | |

| 00301600 | cutting edge width 13-14 mm, 350 mm long | From 1 €102.50 | currently not in stock available expected from 15.06.2025 | | |

| 00301500 | cutting edge width 15-16 mm, 350 mm long | From 1 €112.50 | currently not in stock Delivery time 30 Workdays | | |

| 00301400 | cutting edge width 18-20 mm, 350 mm long | From 1 €98.00 €122.50 | more than 10 in stock available immediately | | |

| 00301300 | cutting edge width 23-25 mm, 350 mm long | From 1 €103.60 €129.50 | only 8 in stock available immediately | |

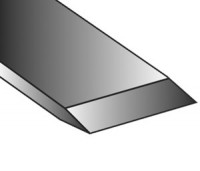

Please select the desired tool length (steel length) and cutting edge width!

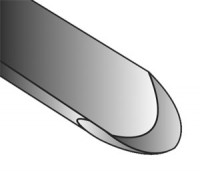

Please note that the hand-forged tools of the brand "Neuhammer" are delivered without hilt.

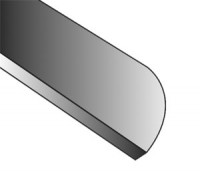

Compared to industrially manufactured mass products, please note that dimensions and shape show slight variations due to the manufacturing technology of hand-forging. In addition, cutting edge shape and sharpness of new tools are not yet ready for use. All tools must first be sharpened. This makes it possible to correct the cutting edge shape according to individual requirements (influencing factors such as wood type, workpiece shape and the like).

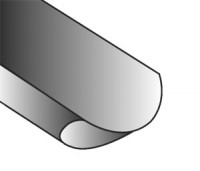

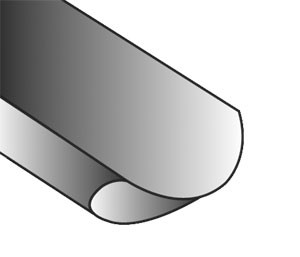

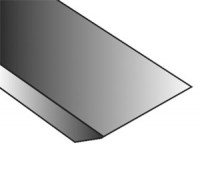

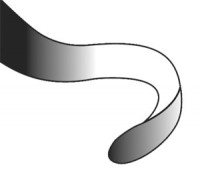

Application: The normal turning gouge, also called long wood gouge, form gouge or spindle gouge, is primarily used for differentiated profiling (throat, carnies) in long wood work. For larger workpiece diameters, where one comes up against limits with the chisel, the spindle shaping gouge is also used in the appropriate size.

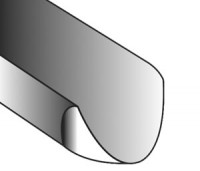

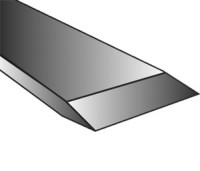

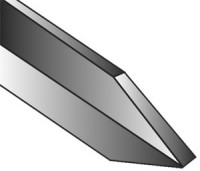

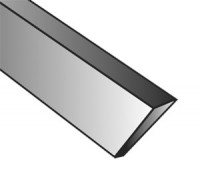

Bevel: The required wedge angle depends not only on the hardness and density of the wood, but also on the respective profile of the workpiece. In general, it can be said that smaller wedge angles (20 - 30º) should be provided for soft wood and larger wedge angles (30 - 50º) for harder woods. For elongated coves, a relatively large chamfer is favorable. For certain workpiece shapes such as narrow fillets, it often proves advantageous to "grind back" the side edges of the cutting edge so that the cutting edge has a relatively small radius. (so-called fingernail grinding).

Working method: After marking the width of the throat, it is advisable for the beginner to first lightly pierce the outer edges of the throat with the chisel tip so that the gouge does not slip off when it is set. The experienced woodturner immediately sets the well-drawn gouge high, roughs the shape, and then neatly finishes the final shape, alternating from right and left (from large to small diameter) in even strokes.

The choice of the width of the gouge depends on the size of the workpieces to be produced and the profile aimed at.

Beginners who do not have enough practice with the chisel use the spindle gouge for the most varied shapes in the long wood sector.

For a basic set-up, the width 13-14mm is recommended.

Examples of use: Columns, furniture legs, railings, candlesticks, handles, stems, cans (external shape), writing instruments, figurative design, grinders, writing instruments, etc.

Seit vielen Jahren benutze ich fast ausschließlich Spindelformröhren von Gläser, bzw. jetzt von Neuhammer und bin sehr damit zufrieden! Sehr gute Qualität und auch Standzeiten überzeugen!