Prices incl. VAT plus shipping costs

more than 10 in stock available immediately

Prices incl. VAT plus shipping costs

more than 10 in stock available immediately

- Order number: 00305500

| Order number | Preview | size | Price Price | Delivery time | Order quantity |

|---|---|---|---|---|---|

| 00305500 | cutting edge width 12 mm, 320 mm long | From 1 €52.40 €65.50 | more than 10 in stock available immediately | | |

| 00305400 | cutting edge width 15 mm, 320 mm long | From 1 €55.60 €69.50 | more than 10 in stock available immediately | | |

| 00305300 | cutting edge width 20 mm, 320 mm long | From 1 €70.80 €88.50 | currently not in stock Delivery time 30 Workdays | | |

| 00305200 | cutting edge width 30 mm, 350 mm long | From 1 €95.60 €119.50 | only 3 in stock available immediately | | |

| 00305100 | cutting edge width 50 mm, 350 mm long | From 1 €123.60 €154.50 | more than 10 in stock available immediately | |

Please select the desired tool length (steel length) and cutting edge width!

Please note that the hand-forged tools of the brand "Neuhammer" are delivered without a handle.

Compared to industrially manufactured mass products, it should be noted that dimensions and shape show slight fluctuations, which are due to the manufacturing technology of the artisanal forging. In addition, the shape and sharpness of the cutting edge are not yet ready for use with new tools. All tools must first be sharpened; this enables the shape of the cutting edge to be corrected according to individual requirements (influencing factors such as type of wood, workpiece shape and the like).

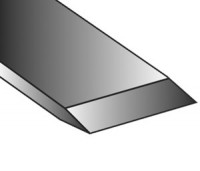

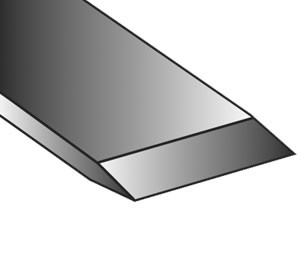

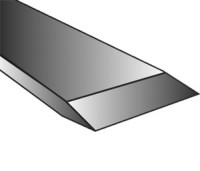

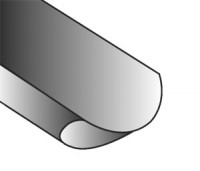

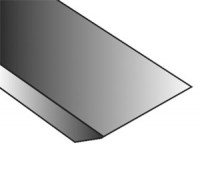

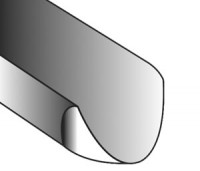

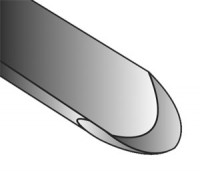

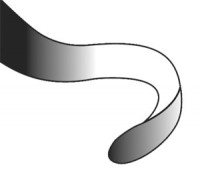

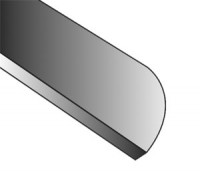

Application: The chisel, regionally also called flat iron, is one of the most important tools of the woodturner when turning long wood. Once the square timber has been turned round with the roughing gouge and the approximate dimensions of the roll to be achieved have been reached, work with the chisel is continued. It is used for form and smooth turning (finishing) and for grooving and parting off. Conical shapes (so-called half or quarter rods) and almost all conical shapes can be produced with the chisel. There are chisels in conical and straight shapes. The straight shapes are advisable for narrow chisels (up to approx. 20mm), as well as for very wide chisels (50-70mm). The conical chisels have proven themselves for strong profiles because they can be guided more flexibly on the hand rest rail.

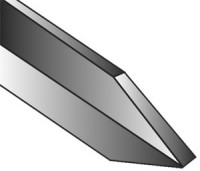

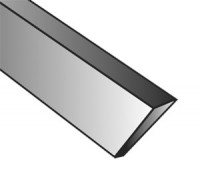

Sharpening: The chisel is sharpened at an angle from two sides to the cutting edge. It is important that the chamfers are the same size on both sides. The wedge angle depends on the hardness, density and the rest of the nature of the wood and the profiles to be executed. The incline of the cutting edge depends on the woodturner's habits and how he guides his tool on the support. It is around 45°.

Working method: Elongated surfaces and curves are cut with the lower half of the cutting edge. The "beard" (obtuse-angled lower cutting corner) is used for turning short curves and notches. The "point" (acute-angled upper cutting corner) is used for grooving and parting.

Application examples: column-shaped workpieces such as handrails, furniture legs, figures, writing implements, handles, etc.

Die Flachmeisel in den verschiedenen Ausführungen überzeugen allesamt mit sehr guter Qualität und außerordentlich guten Standzeiten. Benutze diese in verschiedenen Ausführungen und Schneidenbreiten schon seit Jahren. Ich kann sie nur weiter empfehlen!