Prices incl. VAT plus shipping costs

only 7 in stock available immediately

Prices incl. VAT plus shipping costs

only 7 in stock available immediately

- Order number: 00303000

| Order number | Preview | size | Price Price | Delivery time | Order quantity |

|---|---|---|---|---|---|

| 00303000 | cutting edge width 8-12 mm, 320 mm long | From 1 €122.50 | only 7 in stock available immediately | | |

| 00323101 | cutting edge width 14-16 mm, 350 mm long | From 1 €141.20 €176.50 | only 10 in stock available immediately | |

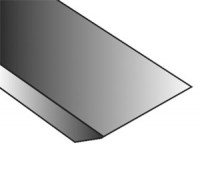

Please select the desired tool length (steel length) and cutting edge width!

Please note that the hand-forged tools of the brand "Neuhammer" are delivered without hilt.

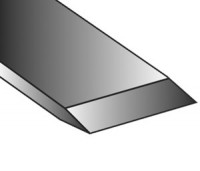

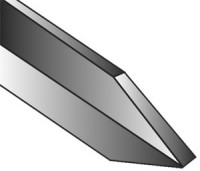

Compared to industrially manufactured mass products, please note that dimensions and shape show slight variations due to the manufacturing technology of hand-forging. In addition, cutting edge shape and sharpness of new tools are not yet ready for use. All tools must first be sharpened. This makes it possible to correct the cutting edge shape according to individual requirements (influencing factors such as wood type, workpiece shape and the like).

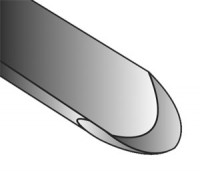

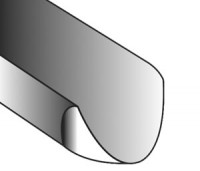

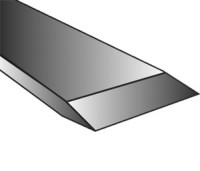

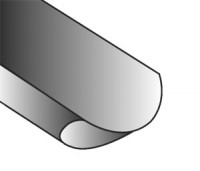

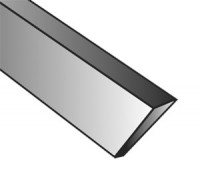

Application: The German gouge has the same cross-section as a crosscut gouge, but is provided with an additional chamfer on the inside of the U-shape. The outside chamfer is usually shorter than the inside chamfer. This tool form is used for turning out hollow forms in end grain. It is also referred to as "overhead" turning. It is also suitable for finishing walls in straight, deep hollow bodies. (cans, tins)

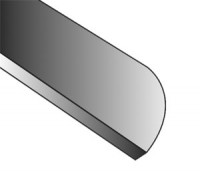

Bevel: The bevel on the inside of the Neuhammer tools is already roughly pre-ground. The external chamfer must be corrected. It must be adapted to the profile to be machined (size of the cavity) and serves as a guide chamfer.

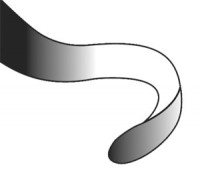

Working method: When working with the German gouge, the same applies as with all other woodturning work: always turn with the wood fiber, never against it. In the special case of hollow turning, this means always working from the center (axis of rotation) outward. The outer chamfer of the gouge is pressed against the face of the workpiece and the cutting edge is guided from the axis of rotation outwards (approximately in the direction of 2:00). It is advisable to drill a hole or at least place a grain in the center of the workpiece to obtain a better starting point.

Examples of use: for concave shapes in end grain such as egg cups, furniture knobs, spinning tops, can lids