No results were found for the filter!

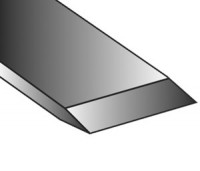

Schmiede Neuhammer (Deutschland)

Neuhammer Flat Chisel Conical (Forged) different sizes From €83.50 *

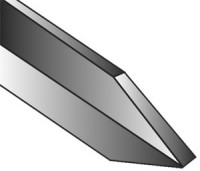

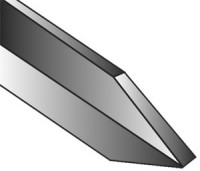

Schmiede Neuhammer (Deutschland)

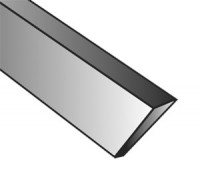

Neuhammer Diamond-Shaped Parting Tool without Groove, (Forged) different sizes From €74.00 * €92.50 *

Schmiede Neuhammer (Deutschland)

Neuhammer German Hollowing Gouge (Forged) different sizes From €122.50 *

Schmiede Neuhammer (Deutschland)

Neuhammer Scraper Straight (Forged) different sizes From €67.60 * €84.50 *

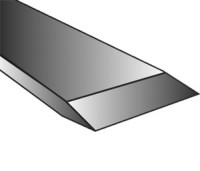

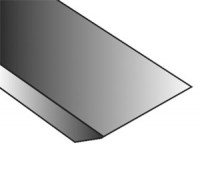

Schmiede Neuhammer (Deutschland)

Neuhammer Flat Chisel Straight (Forged) different sizes From €52.40 * €65.50 *

Schmiede Neuhammer (Deutschland)

Neuhammer Parting Tool with Flat Groove (Forged) different sizes From €74.80 * €93.50 *

Schmiede Neuhammer (Deutschland)

Neuhammer Parting Tool without Groove (Forged) Length 320mm, width 3-4mm €66.80 * €83.50 *

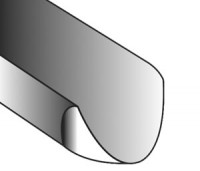

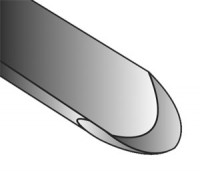

Schmiede Neuhammer (Deutschland)

Neuhammer Woodturning Hook Tool "Erzgebirge" (forged) different sizes From €70.00 * €87.50 *

Schmiede Neuhammer (Deutschland)

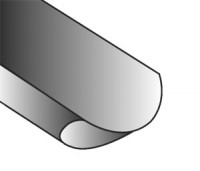

Neuhammer Scraper Fully Rounded (Forged) different sizes From €100.40 * €125.50 *

Schmiede Neuhammer (Deutschland)

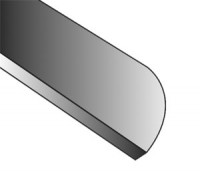

Neuhammer Scraper Left Rounded (Forged) different sizes From €97.20 * €121.50 *

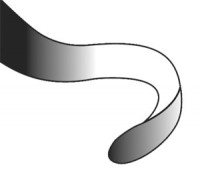

Schmiede Neuhammer (Deutschland)

Tree chisel for the production of rolled chip trees from the Ore Mountains €95.50 *

You have last looked at the following articles: